Isopropyl Alcohol (IPA) has been widely used in printing industry, especially in offset lithography printing. It has some advantages in reducing surface tension of fountain solution and provides better wetting. It also acts as a “coolant” to remove the heat from rollers and the ink rapidly.

However, the highly volatile properties of isopropyl alcohol (IPA) have brought in the concern of few authorities such as Environmental Protection Agency (EPA) and Occupational Safety and Health Administration (OSHA). These authorities are enforcing those solvent users to eliminate or limiting the usage of volatile organic compounds (VOC) in any sectors. Therefore, the usage of IPA or any volatile solvents in printing industry have been constrained.

As our customers are well aware, Shadowfax offers a comprehensive range of alcohol free fountain solutions covering all press types and all dampening systems. Therefore, it is important, that we differentiate between an alcohol free fountain solution and an alcohol substitute. As the name suggests, alcohol free fountain solution is designed to run on presses equipped with an alcohol dampening system, but without dosing any into it. In contrast, an alcohol substitute is not a fountain solution, but a fountain solution additive, which is dosed into the press readily, diluted fountain solution in a similar way to alcohol, so in effect it performs the functions of alcohol in the fountain solution.

Shadowfax recognised that for many of its customers, even if alcohol free fountain solution may be a desirable choice, there are often number of practical reasons, why it is not the 1st option. The reasons could be that the press is old, the water quality is not the best and, the press room is not temperature controlled, the rollers and the roller settings are not exactly right, etc.

Such customers would however still like to run without IPA. Shadowfax responded to these customers by developing CREST Alconov, which will offer almost all the positive aspects of IPA. Below are the advantages of CREST Alconov against IPA:

Flammability

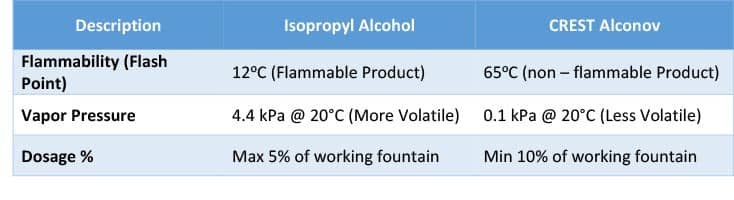

A common Isopropyl Alcohol (IPA) for printing usage has a very low flash point at about 12°C. Therefore, it is categorized as flammable product. This solvent must be handle with extra care.

On the other hand, CREST Alconov has a flash point much higher than room temperature. It is at about 65°C. Therefore, it is a non-flammable product. The fire or explosion hazard is minimized when CREST Alconov is used under normal press operating conditions.

Concentration of CREST Alconov vs. Isopropyl Alcohol

It is recommended to start CREST Alconov at 5% to the working fountain solution. (i.e. 500 ml of CREST Alconov add to 10 litres of working fountain solution). Then, slowly decrease according to the suitability.

If IPA were used in place of CREST Alconov, a minimum of 1.0 litre of IPA is required added into 10 litres of working fountain solution to reach a concentration of 10%.

Therefore, the concentration of IPA would be approximately two (2) times more than CREST Alconov.

Vapour Pressure & Evaporation Rate

Vapour pressure is defined as the pressure exerted by vapour with its solid or liquid form at a given temperature. The high vapour pressure denoted that the substance has more volatility.

Isopropyl Alcohol – 4.4 kPa @ 20°C

CREST Alconov – 0.1 kPa @ 20°C

From the above data, we understand that the vapour pressure of IPA is 44 times greater than CREST Alconov. We can conclude that IPA is much more volatile than CREST Alconov.

Therefore, replenishment of IPA is required during the press run due to evaporation loss.

Cost Efficiency

From the above findings (Table 1), we can conclude that CREST Alconov is more cost effective than IPA. Only a low dosage of CREST Alconov is required to run the press with easy handling. The slow evaporating rate of CREST Alconov will be an advantage when regulating the fountain solution mixture, even at high temperature.

CREST Alconov – therefore offers the customer the best of both worlds, with the added option of eventually progressing to alcohol free running, once the customer had the time and the resources to address the issues which prevent alcohol free running.